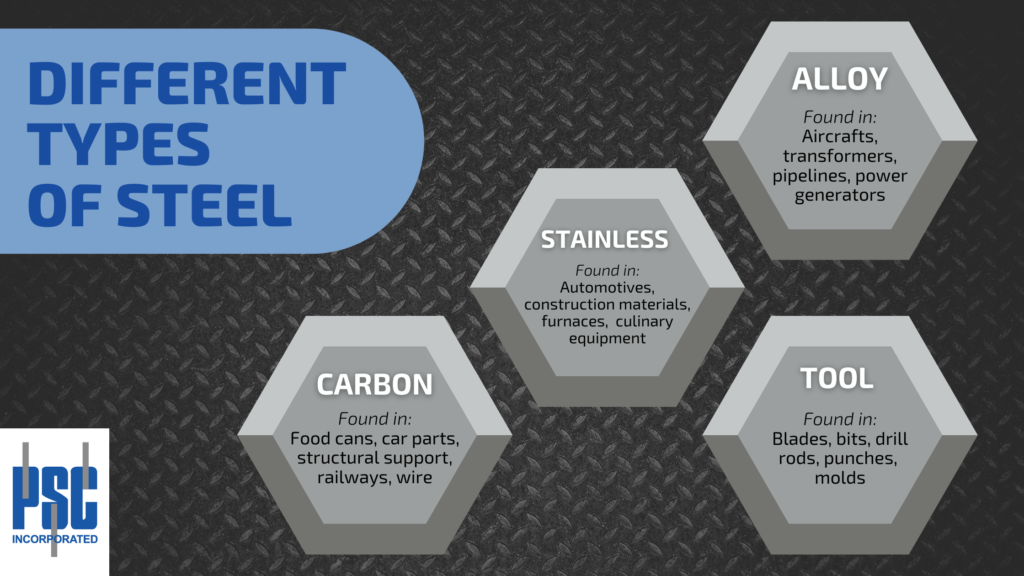

Since steel is so versatile in its uses, reliable steel companies like Pennsylvania Steel offer various types of steel for the multitude of projects our customers execute. The material’s type is determined by two main factors: the individual amounts of its alloy components (such as carbon and iron) and its production process.

The Four Main Types of Steel

Although there are technically over 3,500 types of steel available on the market with varying physical properties, we’re going to focus on the four primary types of steel:

- Carbon steel

- Alloy steel

- Stainless steel

- Tool steel

Learning the differences between these will help you understand which is the best for your project and why it’s the best for the job.

Carbon Steel

As the name suggests, carbon steel contains mainly carbon and iron, and a trace of other elements (such as magnesium or chromium). There are three main subcategories of carbon steel which include:

- Low Carbon Steels (less than 0.3% carbon) – Most common on the market because it’s relatively inexpensive, easy to form, and highly ductile. Commonly used for pipes, domestic appliances, wires, medical equipment, etc.

- Medium Carbon Steels (0.3% – 0.6% carbon) – It’s strong, but it is difficult to form due to low ductility and toughness. Commonly used in machinery parts, cranks, gears, etc.

- High Carbon Steels (greater than 0.6% carbon) – Hardest and toughest variety, but is difficult to weld, cut, and form. Commonly used for railways, bars, spring steel, etc.

As we mentioned above, each type of carbon steel offers different levels of strength, ductility, and workability that make them suitable for different applications.

Generally, this type of steel is used in materials such as construction equipment and automotive components. In fact, carbon steel accounts for about 90% of total steel production in the entire industry because it’s inexpensive to produce and durable enough for use in large commercial projects.

Alloy Steel

The name “alloy steel” suggests a large mix of different elements in addition to the characteristic carbon and iron combination. Examples of common additives are:

- Magnesium

- Chromium

- Nickel

- Silicon

- Molybdenum

- Titanium

- Copper

The percentages of these elements will determine the appropriate application for the material. Manipulating these proportions changes the steel’s properties, such as heat resistance, hardness, and ductility. Companies often utilize this type of steel to produce commercial equipment like aerospace and aircraft components, transformers, pipelines, and power generators.

Stainless Steel

Steel in this category contains 10-20% chromium, making it incredibly resistant to corrosion and staining. This concentrated chromium coating also makes this material rust-proof. Classified by their microscopic structures, there are three subsets of stainless steel:

| TYPE OF STAINLESS STEEL | GRADE | PROPERTIES | % ALLOYING ELEMENTS | COMMON USES |

|---|---|---|---|---|

| Austenitic | 300 | non-magnetic and non-heat-treatable | 18% chromium 8% nickel <0.8% carbon | kitchen and food processing equipment |

| Ferritic | 400 | magnetic | 10.5-27% chromium <0.1% carbon | heat exchangers and furnaces, auto parts |

| Martensitic | 400 | magnetic and heat-treatable | 11-17% chromium <0.4% nickel <1.2% carbon | cutting tools, dental and surgical equipment |

Stainless steel is a highly versatile material due to its notable resistance to heat and discoloration. Its unique resilience makes it the best type of steel for a number of industries, ranging from culinary and catering to standard machinery and cars. Check out our guide on how to weld stainless steel to help your next project.

Tool Steel

A combination of carbon and alloy steel, tool steel generally offers high hardness and abrasion resistance. These features, along with its superior ability to retain its shape, make it the ideal material for composing various tools. Surgical equipment, drills, dyes, bits, molds, and punches are examples of instruments made using tool steel.

Manufacturing quality tools requires quality steel components. PA Steel produces a number of different tool steels, which consist of carbon and alloy steels. Tool steel offers advanced abrasion resistance and toughness. We stock many different tool steel grades, including:

- Air Hardening (A-Grades)

- High-Carbon High-Chromium (D-Grades)

- Shock Resisting (S-Grades)

- Mold Quality/Hot Work (H-Grades)

- Oil Hardening (O-Grades)

- Water Hardening (W-Grades)

To learn more about our tool steel inventory, grades, and their applications, check out our detailed Tool Steel Guide.

Choosing The Best Steel For Your Project

As previously mentioned, the selected steel’s type identifies its key properties, including ductility, hardness, weldability, and more. Naturally, these qualities will determine the applied uses of the chosen metal.

In other words, selecting the wrong metal can prove detrimental to the quality of your project. For example, high alloy or low carbon steels are most effective in extremely cold temperatures because they retain high tensile strength even in frigid conditions. Therefore, residential and commercial structures being built in freezing climates should use these types of metals in their structural designs.

If you’re unsure about what your metal project requires, feel free to contact the specialists at Pennsylvania Steel for further insight into your ideal metal for the job. We can help you confirm your choice and walk you through your potential options for a high-quality result!

Contact PA Steel For a Custom Quote

Regardless of the job you take on, PA Steel offers a wide stock of the different types and grades of steel to help you prepare for your next project. Our knowledgeable staff has years of expertise, so feel free to contact the steel warehouse closest to you with any questions or to receive an estimate. Contact our Pennsylvania, New York, New England, Virginia (Richmond), North Carolina (Charlotte), and Ohio steel supply warehouses.

Share This Post

Recent Posts

How to Choose the Right Grade of Tool Steel

Using tool steel in manufacturing or construction is a common practice, but tool steels are

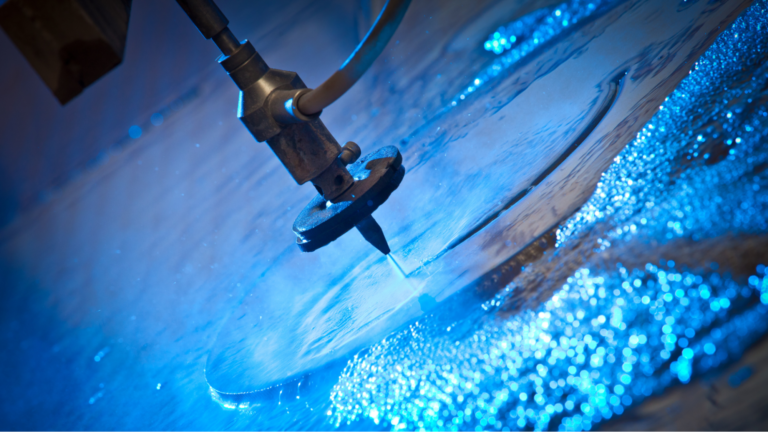

How to Cut Steel Plate

Cutting through a material as strong as plate steel requires specialized machinery and training. The

Alloy Steel vs Stainless Steel: Which Is Better for Your Project?

The choice you make between alloy steel and stainless steel for your project is critical.